PP PE flake recycling line is used to convert rigid PP PE plastic waste into recycled plastic pellets. The whole production line includes plastic crusher, plastic washing machine, plastic dewatering machine, plastic granulator, cooling tank, pellet cutting machine and so on.

The standard capacity of Shuliy PP PE flake recycling line is 200-3000kg/h. We provide larger capacity according to different production requirements, applications, raw materials and so on.

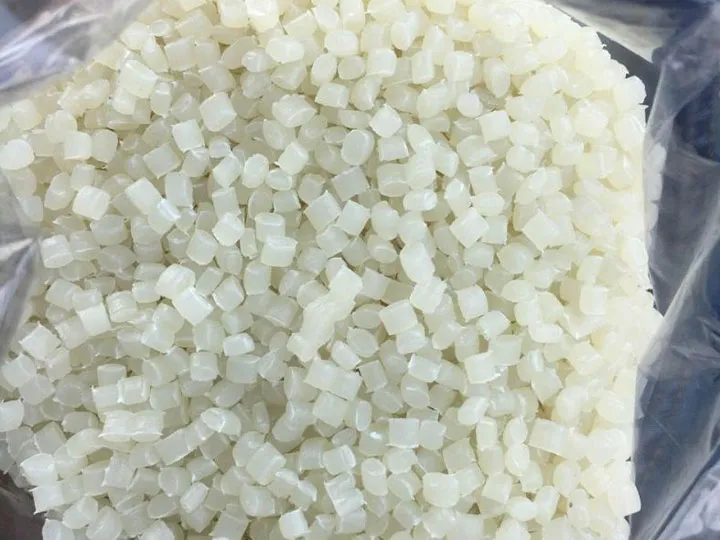

Raw materials and final products

The raw materials of waste plastic granulation line mainly include waste rigid PP PE plastic products, such as plastic buckets, plastic pots, toys, plastic boxes, plastic sheets and so on. Through the process steps of crushing, cleaning and melting, these waste plastics are converted into recycled PP PE plastic pellets.

Process flow of PP PE flake recycling line

- Material pre-treatment: Firstly, the waste rigid PP PE plastic products need to go through pre-treatment processes such as crushing and cleaning to remove impurities and pollutants to ensure the quality of raw materials.

- Melting and extrusion: The pre-treated plastic pieces are fed into the plastic pelletizer, where they are melted into melt through high temperature and high pressure. The melt is then extruded into filaments through plastic extruder.

- Cooling and cutting: The extruded plastic filaments need to be rapidly cooled in a cooling tank to solidify into pellet form. The pellets are then cut into desired lengths through a plastic pellet cutter.

- Recycled pellet collection: The cut recycled pellets are collected and stored ready to be used for subsequent product manufacturing.

Video of waste plastic granulation line

Machines for plastic recycling plant

Inclined belt conveyor

In the PP PE flake recycling line, waste PP and PE plastics are first conveyed by inclined belt conveyor to plastic crusher.

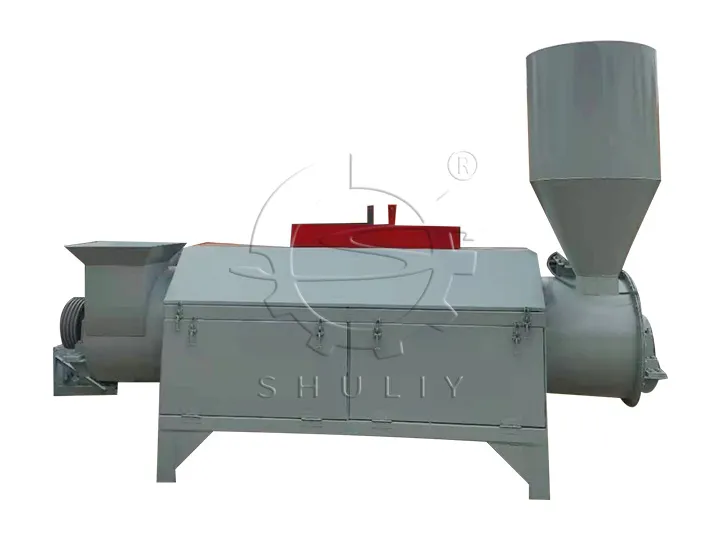

Plastic crusher machine

Plastic crusher machine physically shredder waste plastic into smaller pieces. This helps to reduce the size of the plastic in subsequent steps.

Plastic rinsing tank

The crushed plastic pieces are fed into the plastic rinsing tank to remove impurities and residues from them.

Plastic drying machine

After washing, plastic chips need to have excess moisture removed for further processing. The plastic drying machine shakes the moisture out of the plastic by rotating them at high speed, making them more suitable for the subsequent pelletizing process.

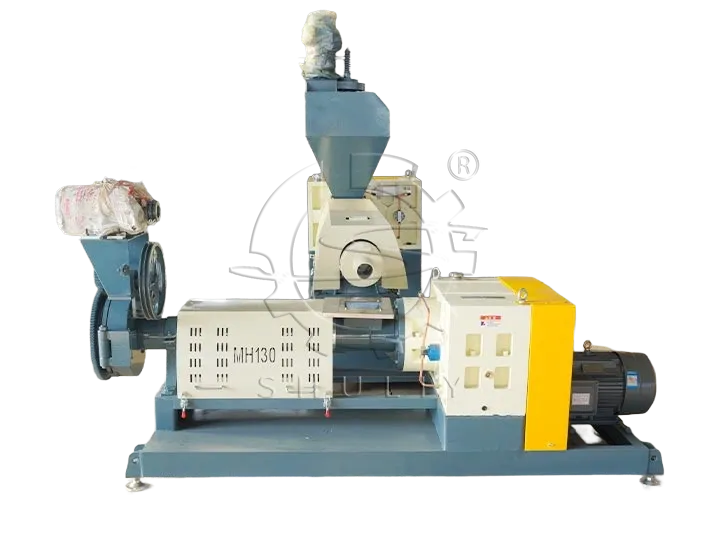

Plastic extruder machine

Plastic pelletier is the most critical machine in PP PE flake recycling line.It melts and extrudes plastic at high temperatures. The plastic melt flows out through the main machine and is then extruded into plastic strips through the auxiliary machine.

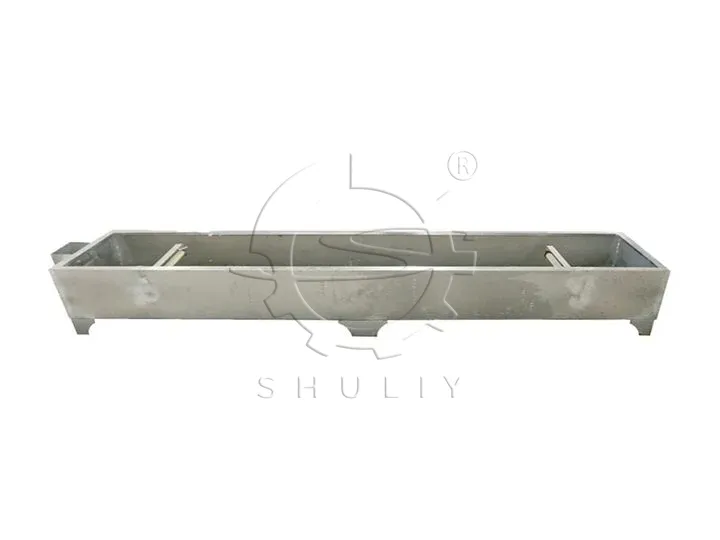

Cooling tank

Plastic strips extruded from plastic pelletizer need to be cooled quickly to maintain their shape and quality. The cooling tank achieves rapid cooling by circulating cold water through the plastic strip.

Plastic cutter machine

Plastic cutter machines are used to cut long strips of granules into the desired length to meet customer requirements. This step customizes the size of the final product.

Storage bin

The storage bin is used to store the manufactured pellets for subsequent packaging and transport.

Video of plastic recycling equipment

Features of plastic recycling plant

- PP PE flake recycling line relies on automatic control with high production efficiency and pelletizing capacity. The production efficiency is as high as 200- 3000kg/hour to meet the market demand.

- Through a finely tuned manufacturing process, PP PE flake recycling line produces high-quality, consistent plastic pellets to meet the needs of different industries.

- The PP PE flake recycling line can all be customized to meet specific customer requirements, including pellet size, production capacity and material type.

- These plastic recycling equipment offer superior quality, low energy consumption and long service life, reducing maintenance and replacement costs.

FAQ

Why choose Shuliy PP PE flake recycling line?

Shuliy, as a renowned plastic pelletizing line manufacturer, upholds years of experience and expertise in providing high-quality products and services. Shuliy PP PE flake recycling line has an advanced design that can adapt to different types of plastics, which makes the production of recycled pellets easier and more efficient.

What plastics is this waste plastic granulation line suitable for?

The PP PE flake recycling line is suitable for waste PP, PE, HDPE and other plastics. This includes waste plastic tubs, buckets, plastic containers and other common plastic products. With this plastic flake pelletizing line, these waste plastics can be efficiently processed and converted into recycled pellets for the manufacture of new plastic products.

What are the factors that affect plastic pelletizing line price?

Plastic pelletizing line price is affected by a number of factors, including the size, capacity, configuration and brand of the PP PE flake recycling line. Higher capacity and advanced technology configurations typically result in higher prices. In addition, customization requirements may also increase the cost. Buyers need to choose the right product for their needs and budget.

Can customers send samples to customize the granulation line?

Yes, Shuliy welcomes customers to provide samples to customize the PP PE flake recycling line. This ensures that the configuration and performance of plastic recycling plant matches the characteristics of the waste plastic to achieve the best results. Customers can always contact Shuliy to discuss customization needs and provide samples for testing and validation.